You will not be allowed to compare more than 4 products at a time

View compare

Description

Description

Airlite BFS B101 Air HG

Introducing the Loongze Reel Airlite BFS (B101 AIR HG) – precision-cut from 6061-T6 aluminum for 30% greater strength than traditional die-casting. Experience adjustable brake resistance matched to line spool speed, with a 5x44 die setting. The pure carbon brake disc and high-hardness T7 plate ensure smooth braking even under significant force. The innovative clutch mechanism, line spool bearing system, and DGFX drive gear attachment enhance durability and reduce noise. Our industry-first dual-support line spool structure, made from aerospace-grade aluminum, ensures strength without sacrificing lightness. Perfect for finesse casting, handling weights as low as 1 gram. Loongze B101 AIR HG: Precision, Strength, Finesse.

Color: Gunsmoke, Gold, Purple

-

MBS Matrix Braking System

MBS Matrix Braking SystemThe braking resistor intervention varies according to the rotation speed of the wire spool, providing a more stable linear resistance. There are 5 adjustable invention levels, combined with 44 adjustable permanent magnet resistors, forming a 5X44 matrix resistance setting.

Integrated metal frame

Integrated metal framePrecision CNC-cut 7075-T7 aluminum bar, one-piece body that integrates the reel seat and front cover into the main frame. 30% stronger than traditional die-casting process.

Drive gear fixing mechanism

Drive gear fixing mechanismThe DGFX drive gear fixing mechanism, with its innovative design, effectively allows the axial movement of the main gear, thus improving the durability and stability of both large and small gears.

Think of the main gear as the central component that drives the entire system, much like a car's engine. Just as a motor is well anchored to prevent excessive vibration and ensure smooth operation, the drive gear's mounting mechanism holds the main gear in place, preventing any unnecessary wobble or shifting. This stability is essential to maintaining the integrity of the gear system, especially when dealing with heavy loads or high-speed rotations.

By eliminating axial movement, this mechanism minimizes gear wear, including the risk of damage or premature failure. It acts as a solid foundation, allowing gears to operate more efficiently and reliably over time. Whether it's large gears handling heavy loads or small gears powering complex movements, the benefits of this innovative design extend to a variety of applications.

In summary, the drive gear mounting mechanism is a sophisticated solution that provides stability and durability to gear systems, ensuring optimal performance and longevity. Its innovative design effectively improves axial movement, thus improving the reliability and overall functionality of gears, regardless of their size or intended use.

Floating ball bearing system

Floating ball bearing systemFloating ball bearing system

The innovative floating line spool bearing system can effectively reduce axial movement and noise generated during high-speed casting, thereby improving casting sensitivity and stability.

Soft release system

Soft release systemThe newly designed clutch mechanism incorporates a special Teflon washer between the clutch plate and the main body. The torsion spring installation hole features an ultra-strong PEEK lining, allowing smooth movement without lubrication and an exceptionally long service life of 200,000 wear-free cycles. In addition, it effectively solves corrosion problems in high-humidity and high-salt environments.

Smooth and powerful braking system

Smooth and powerful braking systemThe pure carbon brake disc, combined with the high-hardness T7 machined brake plate, provides a smooth and stable braking system. The thickened brake plate can prevent damage to the main gear bearings even under high braking force when fully engaging with large fish.

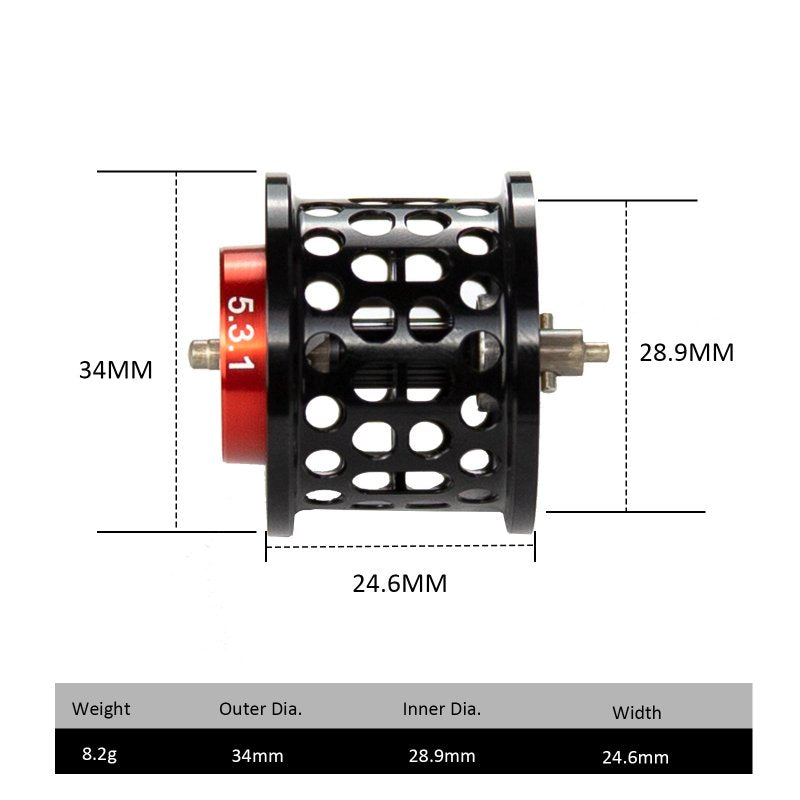

FEATURESARTICLE NAME SKU CODE TO RECOVER BEARINGS GEAR RATIO Drag power Coil Specifications WEIGHT LINE CAPACITY Loongze B101 Air HG aircraft B101 Air HG (left) 75 cm (29.5 in) per crank line 10+2+1 7.1:1 4 kg (8.8 lb) Weight: 8.2 g

Outer diameter: 34 mm

Inner diameter: 28.9 mm

139 g (4.9 oz) PE line 0.6 lb/100 m Loongze B100 Air HG B100 Air HG (right) 75 cm (29.5 in) per crank line 10+2+1 7.1:1 4 kg (8.8 lb) Weight: 8.2 g

Outer diameter: 34 mm

Inner diameter: 28.9 mm

139 g (4.9 oz) PE line 0.6 lb/100 m